Cement manufacturing

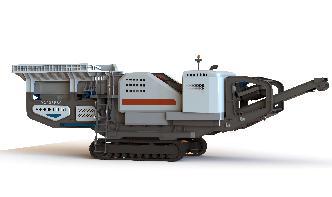

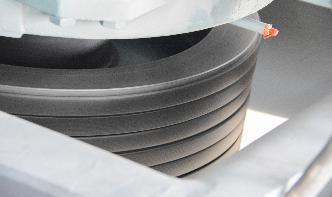

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the 'raw feed' or 'kiln feed' and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.