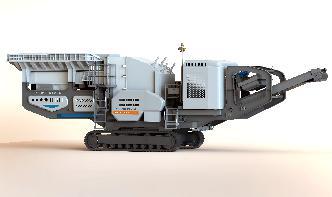

process mining lead ore

Besides the ore itself, only a few raw materials are necessary for the refining of lead. The ore concentrating process requires pine oil, alum, lime, and xanthate. Limestone or iron ore is added to the lead . Read More . Lead Mineral Fact Sheets Australian Mines Atlas. At the surface, the ore is subjected to additional crushing and fine grinding. A flotation process separates the lead and ...