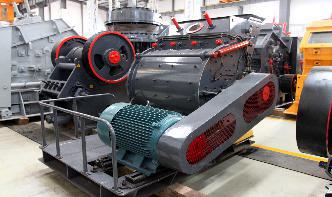

Rotary drum dryer system,working principle and design PALET

Rotary drum dryer by Palet Machinery is specially designed for drying the sawdust, wood shavings, wood chips, woodblocks, rice hull, chicken manure, grass, bean dredges, cassava residue, cassava residue, sludge,etc. The structure of the rotary dryer adopts the means of cylinder marginal transmission, flange connection, direct heat transfer.; Large capacity and fully automatic.