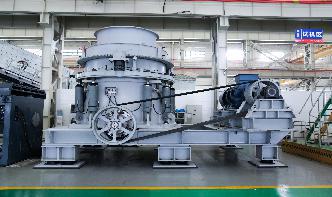

Loesche. Grinding Mills for Ores and Minerals. LOESCHE has more than 100 years of experience in the comminution of cement, raw material, clinker, coal, slag and minerals and its vertical roller mills form the core of many plants used for the drygrinding process of these materials.