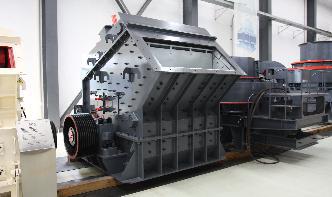

Industrial Roller Mill | Roller Mill Manufacturer ...

Roller mills are industrial mills that uses cylindrical rollers to crush and grind material instead of flat plates like other pulverizers. The Williams Roller Mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why Williams is one of the leading roller mill manufacturers is their ease of use and maintenance.