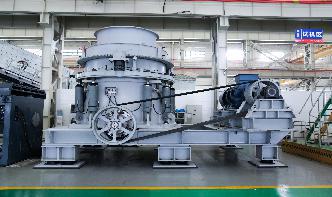

HUIHE MININGPARTS CO., LTD

Huihe Miningparts Co.,ltd is specialized in design, manufacturing of casting wear parts like grinding balls, ball mill liners, crushers etc. Our marketing offices offers regular onsite technical and aftersales services, to meet our customers milling targets by providing grinding solution, milling system adjustment.