Iron Ore | Geoscience Australia

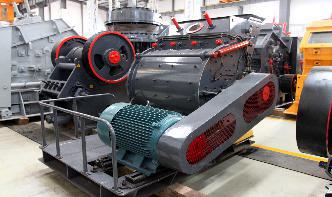

Highgrade hematite ore is referred to as direct shipping ore (DSO) because after it is mined, the ores go through a relatively simple crushing and screening process before being exported for use in steelmaking. Australia's hematite DSO from the Hamersley region in Western Australia averages from 56% to 62% iron. Like hematite ores, magnetite ores require initial crushing and screening, but ...