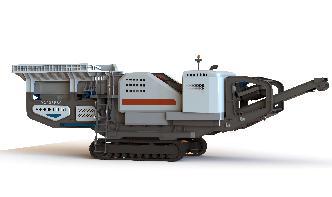

Rock Crushers

Usually, a crushing plant that can process 1000s of metric tons per operating day will consist of a single primary crusher, a single screen, a single secondary cone crusher, and associated conveyor belts. The discharge from both primary and secondary crushers is directed to the screen. Screen oversize serves as feed to the secondary crusher while screen undersize is the finished product. For ...