Cement Manufacturing Process | Phases | Flow Chart ...

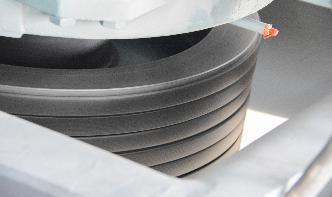

· There is a horizontal filled with steel balls. Clinker reach in this rotating drum after cooling. Here, steel balls tumble and crush the clinker into a very fine powder. This fine powder is considered as cement. During grinding gypsum is also added to the mix in small percentage that controls the setting of cement. Rotating ball mill. Cement Manufacturing Process Phase VI: Packing and Shipping ...