Cement Process Energy Saving

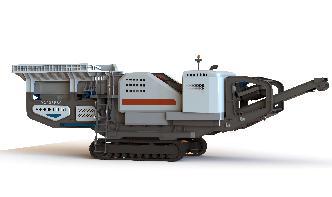

Dry Process Raw Material Grinding System b. Closed Circuit Separator is added. Coarse dust made in milling is separated and recycled to mill. Drying is done within mill. c. Closed Circuit Energyefficient vertical roller mill (VRM) is employed. VRM is also spacesaving. Figure 4 Dry Process Raw Material Section BT : Blending tank ST : Storage tank