cement mine and plant

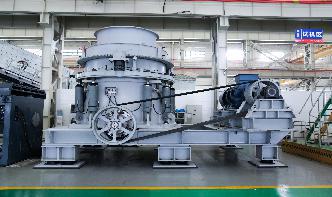

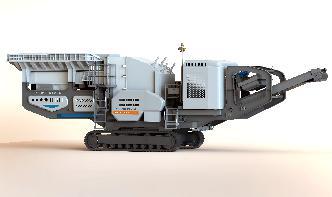

Crushing plant, which crushes the run of mine ore, then conveys the crushed ore to the suitable storage bin. The ore is sent to the crushing plant, where the primary jaw crusher reduces the material, then sends it to a secondary cone crusher, where it is further reduced in size. Finally a series of short head cone crushers reduce the ore to around a 1/4 inch in size.